Rooftop Packaged Unit

Rooftop Packaged Unit Water Chiller

Water ChillerModel No.: RTU12~RTU300

Brand: Amrta or OEM

Type: Evaporative Air Cooler

Air Tube Material: Galvanized Sheet

Corrosion Durability: General

Operating Voltage: 380/400 VAC

Noise Level: Low

Mounting: Floor Standing

Lifetime: 15~20 years

Certification: CE

Condition: New

Application Fields: Mechanical Engineering, School, Airport, Shopping Mall, Industrial Buildings

Refrigerant: R410A/R407c/R134A/R22

Compressor: Danfoss/Copeland/Panasonic/Daikin

Cooling Capacity: 12kw-300kw

Packaging: Plywood Package or Plastic Film Wrapped

Productivity: 600PCS/Year

Transportation: Ocean

Place of Origin: China

HS Code: 8418612090

Port: Qingdao,Shandong,China

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF

Recognized worldwide for their reliability and efficiency, the Amrta Energy Recovery Rooftop packaged unit are self - contained unit that are the ideal, economical solution for a wide range of commercial applications – hypermarkets, supermarkets, commercial buildings, warehouses and other industrial buildings - as well as residential use. From a single unit you can experience the production of comfort cooling, heating, supply of an adjustable volume of fresh air, and even free cooling. When you turn to the Amrta Rooftop Packaged Unit range you'll benefit from Amrta's dedication to constant development of the range in order to deliver the latest state of the art rooftop solutions.

● Industrial buildings and logistic centers

● Wide choice of communication interfaces

The HR system is now widely applied in residential, commercial, industrial applications. Practically, applications which demand the higher quality air and fresh air rate are strongly recommended.

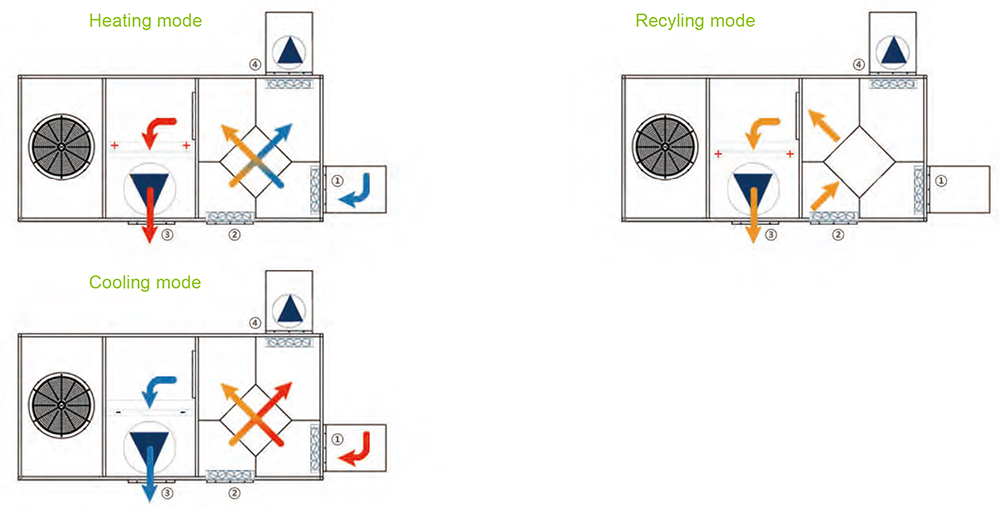

Plate heat recovery

① Fresh air ② Return air ③ Supply air ④ Exhaust air

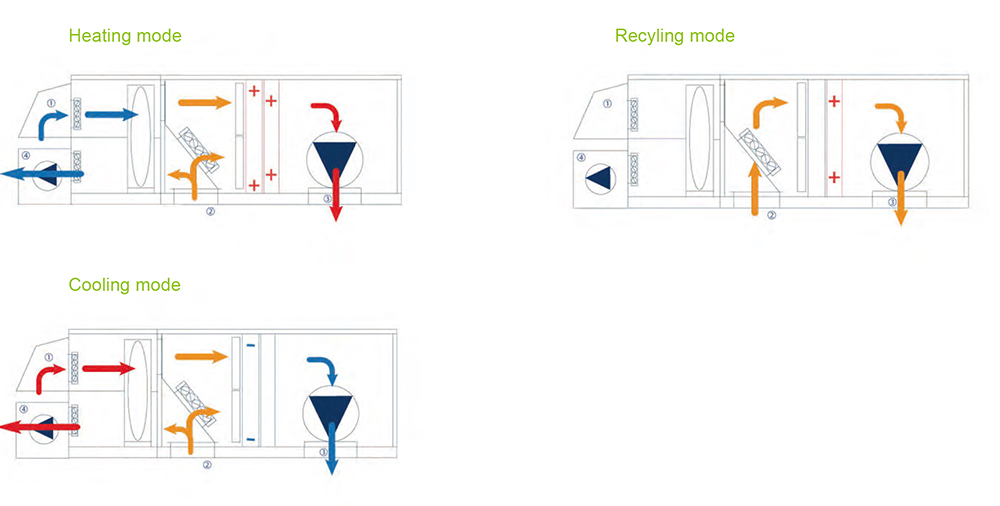

Wheel heat recovery

① Fresh air ② Return air ③ Supply air ④ Exhaust air

Technical Data

| Model | RTU45 | RTU50 | RTU60 | RTU75 | RTU90 | RTU105 | ||

| Cooling capacity | kW | 44.5 | 50 | 60 | 70 | 90 | 105 | |

| Heating capacity | kW | 48.7 | 54.3 | 64 | 75.4 | 96.2 | 113.2 | |

| Power supply | 380V / 3Ph / 50HZA | |||||||

| Cooling power input | kW | 17 | 19.5 | 22.8 | 26.7 | 32.9 | 39.7 | |

| Heating power input | kW | 15.6 | 18 | 21 | 24.8 | 30.4 | 36.7 | |

| Start current | A | 168 | 186 | 175 | 199 | 197 | 266 | |

| Working current in cooling | A | 31.7 | 35.6 | 39.9 | 48.3 | 61 | 70.6 | |

| Working current in heating | A | 29.9 | 33.5 | 37.5 | 45.4 | 57.3 | 66.3 | |

| Throttle methods | Thermal expansion valve | |||||||

| Circuits | 2 | 2 | 2 | 2 | 3 | 3 | ||

| Refrigerant | R410A | |||||||

| Compressor | Type | Scroll type 380V / 3Ph / 50HZA | ||||||

| Qty | 2 | 2 | 2 | 2 | 3 | 3 | ||

| Condenser side | ||||||||

| Condenser | Type | Al+copper tube | ||||||

| Axial fan | Qty | 1 | 1 | 1 | 1 | 2 | 2 | |

| Drive | Direct drive | |||||||

| Motor power | kW | 0.25 | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | |

| Air flow | m3 /h | 4600 | 7800 | 7800 | 9000 | 12600 | 12600 | |

| Evaporator side | ||||||||

| Evaporator | Type | Al+copper tube | ||||||

| Centrifugal fan | Qty | 1 | 1 | 1 | 1 | 1 | 1 | |

| Motor power | kW | 3 | 3 | 4 | 4 | 5.5 | 5.5 | |

| Air flow | m3 /h | 7600 | 8500 | 10900 | 12500 | 16000 | 19500 | |

| Drive | Direct drive | Belt drive | ||||||

| External static pressure(Pa) | 250 | 250 | 300 | 300 | 300 | 300 | ||

| Filter | Aluminum frame filter G3 | |||||||

| Noise level dB(A) | 73 | 73 | 73 | 75 | 74 | 75 | ||

| Dimension | L | mm | 2268 | 2268 | 2298 | 2298 | 2878 | 2878 |

| W | mm | 1440 | 1440 | 1650 | 1650 | 2140 | 2270 | |

| H | mm | 1167 | 1167 | 1400 | 1400 | 1964 | 1964 | |

| Weight | kg | 750 | 770 | 830 | 860 | 1160 | 1350 | |

* Performance values refer to the following conditions:

Cooling: room air temperature 27.0°C DB RH 50%, ambient air temperature 35°C;

Heating: room air temperature 20.0°C DB, ambient air temperature 7°C DB / 6°C WB.

** Noise level measured by adopting average value in the noise lab with background noise of 25 dB(A), at a distance of 1.5m high fan speed.

Product Categories : Rooftop Packaged Unit > Energy Recovery Rooftop Packaged